CMMS System

A CMMS Maintenance Management System is a system that supports the maintenance department.

Computerized Maintenance Management System (CMMS)

CMMS is software that contains information on all aspects of maintenance work related to infrastructure and/or equipment.

The main goal of implementing CMMS systems is to automate maintenance activities. This applies to both service and technical departments, as well as all units responsible for ensuring the proper functioning of production processes. By providing easy access to information on equipment maintenance and inventory status, work organization within the enterprise becomes simpler and more efficient. A properly configured CMMS helps prevent unexpected failures and improves communication among key departments of the production plant.

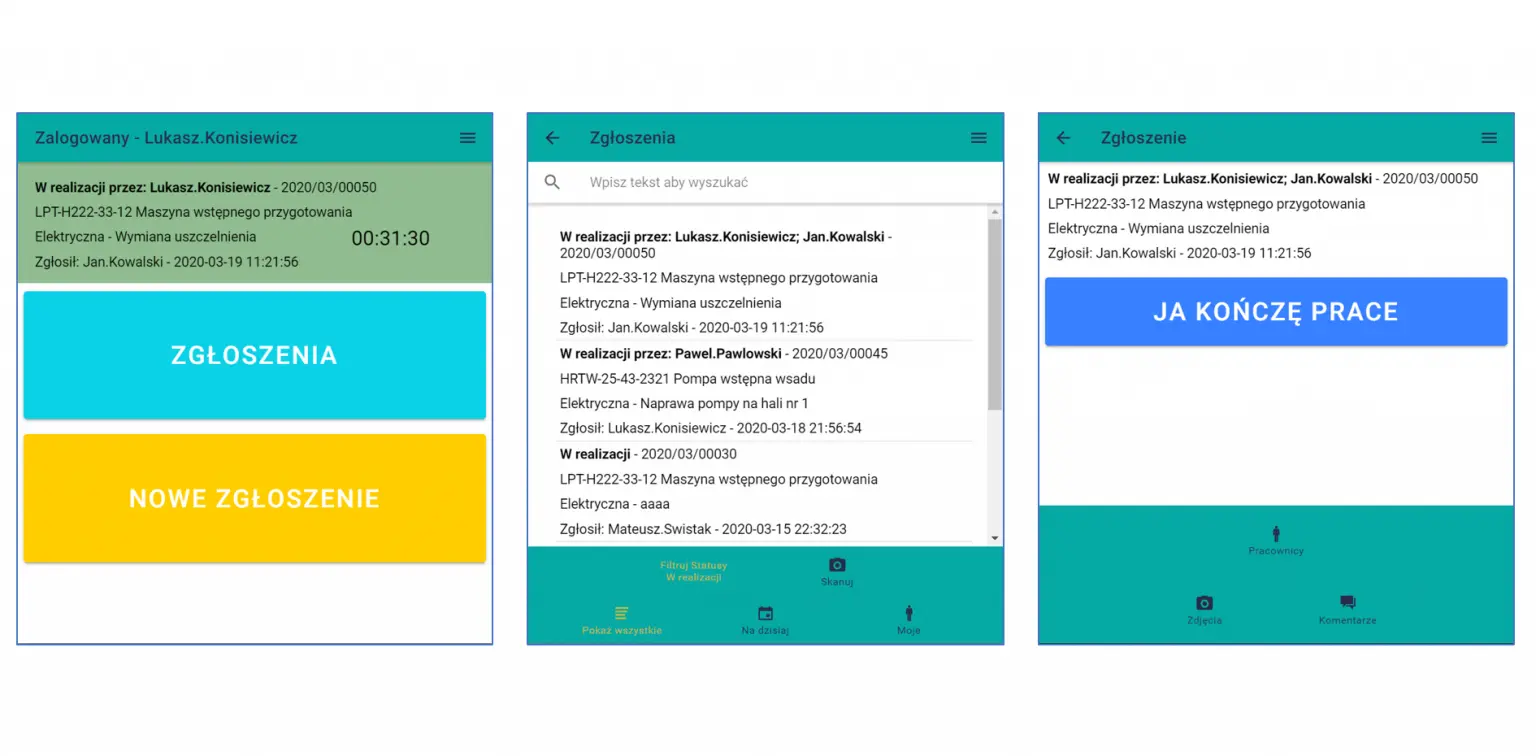

Modern CMMS solutions operate in the cloud, allowing aggregation of critical equipment information within a single database. Technicians can monitor warning signals via mobile devices and respond instantly to malfunctions or failures of individual machines. The ability to quickly identify resource loads allows for adjustments to production schedules and prevents unwanted downtime.

The core components of a CMMS Maintenance Management System include the following modules:

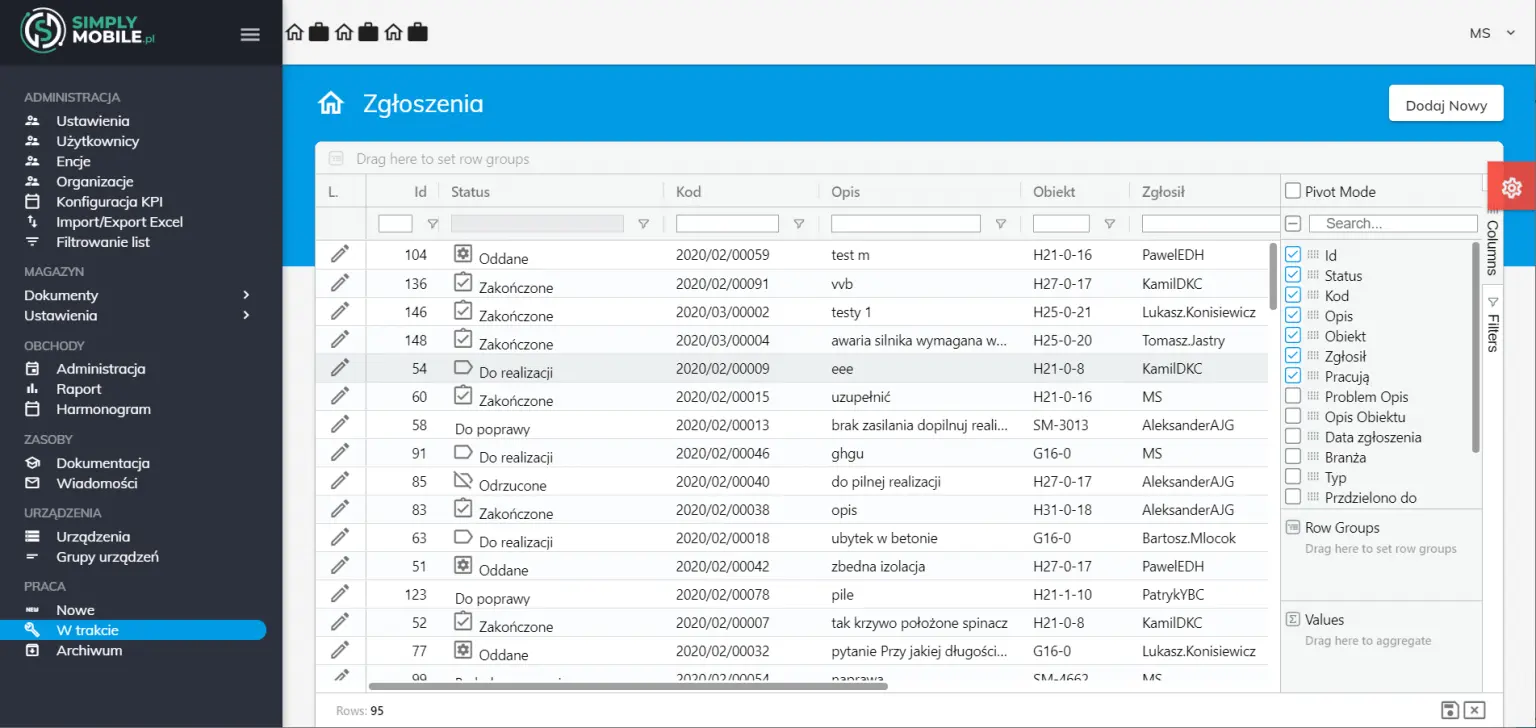

- Work orders and requests

- Preventive maintenance tasks (PM module)

- Work scheduling

- Equipment register and structure

- Inventory

- Technical documentation management

Additionally, common modules in CMMS Maintenance Management Systems include:

- Work logging

- Prediction

- Supplier management

- Procurement

- Work reporting

- Maintenance and investment projects

- Contracts

- Budgeting

Therefore, it is important to remember that which modules to implement in maintenance departments largely depends on the organization’s specific requirements and the existing IT environment.

Finally, it is essential to consider whether the CMMS Maintenance Management System can integrate with other systems such as ERP/SCADA. Such integrations enable synergistic effects and prevent duplication of work across multiple systems.

Based on our many years of implementation experience, we conclude that availability and ease of use are critical elements of CMMS systems. Simple-to-use systems, which require minimal training time, perform best.

By working with simple configurators, technicians do not need extensive knowledge of CMMS systems. Basic computer or mobile device skills suffice. With a clear and highly intuitive interface, data entry by users is fast and efficient.

What Characteristics Define a Reliable CMMS System?

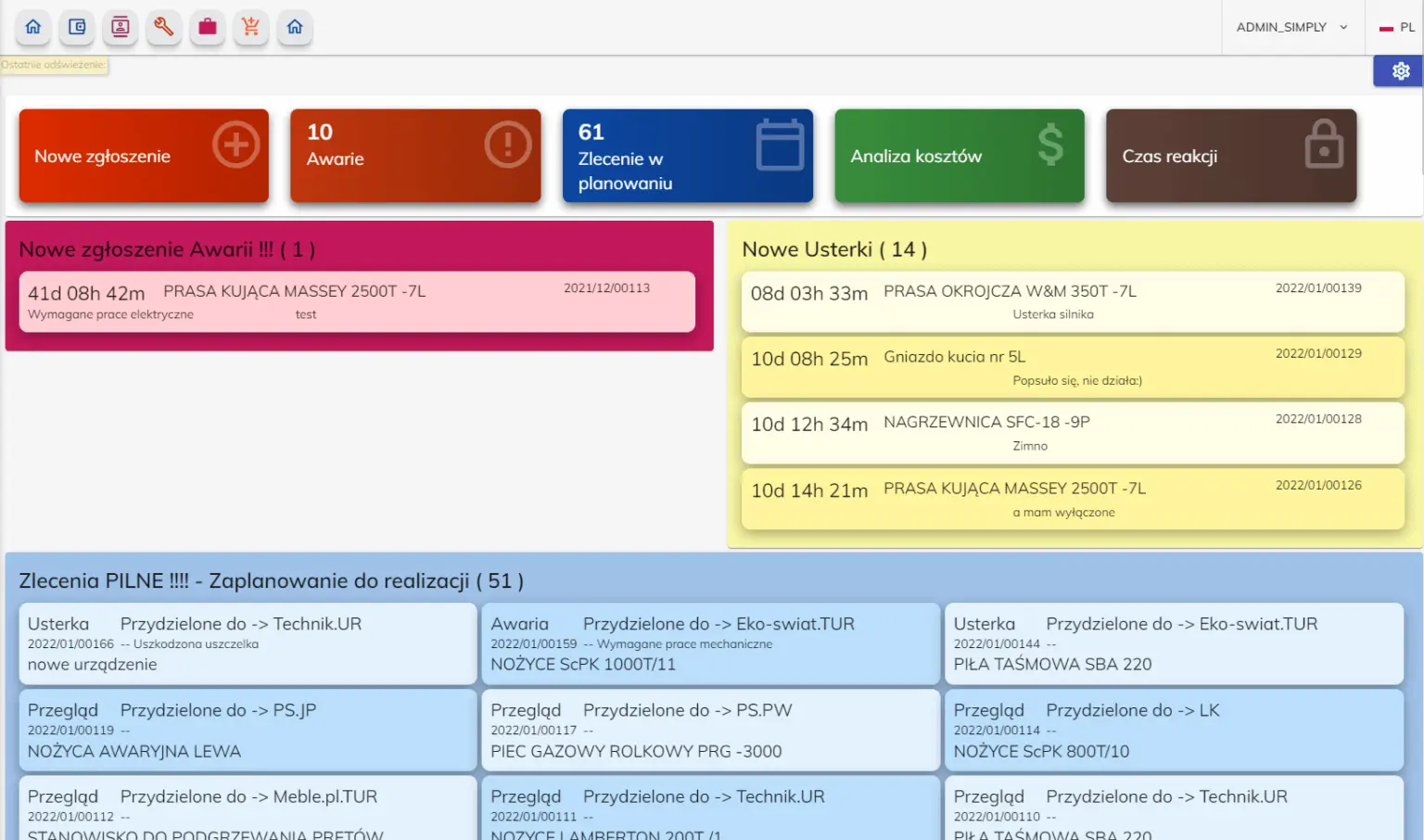

Manufacturing plants employ numerous personnel responsible for effective maintenance, so each department must have constant, unrestricted, and easy access to critical information. The deployed CMMS should be intuitive and easy to navigate so that mechanics, technicians, and machine operators have no doubt about the reports and can use them without delay.

A key feature of a reliable CMMS is its operational flexibility. Introducing new technologies in production processes and software should go hand in hand with efficient expansion of CMMS functions. It is also important to apply changes to user accounts quickly. Acquiring desired permissions should happen without unnecessary delays to maintain the existing level of work organization.

Does the CMMS System Integrate with Other Production Plant Systems?

Extensive machine fleets typically operate using multiple systems. This is essential for the efficient organization of all processes in a production facility. Therefore, the CMMS should enable seamless integration with other systems, so that maintenance tasks also contribute to optimizing processes in other departments.

Proper integration and configuration of the CMMS ensure that all systems in a production plant can operate synergistically. This is reflected in seamless data exchange, which facilitates generating effective reports and creating an efficient electronic document workflow.

Who Are CMMS Systems Intended For?

Primarily for those looking to streamline their maintenance department. We will help you acquire a CMMS that facilitates digitization of various areas of your organization, relieving your employees of burdens such as document handling. A well-designed CMMS is not only an excellent tool for maintenance management but also provides strong support for the warehouse, service department, and procurement.

By implementing a CMMS with us, you will find that it is not just an option for large production plants with complex IT infrastructures. We advocate cloud-based solutions, allowing CMMS deployment wherever you need to boost operational efficiency.

Benefits of Having a CMMS System

Given the availability of a variety of modules, rapid implementation, and seamless operation, CMMS systems remain highly popular among production plants of all sizes and structures. A properly configured CMMS provides extensive automation of communication and production workflows within an enterprise. The machines and equipment in your daily operations can be monitored more accurately, ensuring production continuity and preventing downtime caused by failures or malfunctions. A CMMS is also a milestone in digitization. It goes without saying that paper-based documents cause numerous issues. Incorrectly completed or lost documents can expose a company to financial losses. Therefore, having a system that not only stores important documentation but also enables rapid retrieval is invaluable.

Additionally, with a properly configured CMMS, your warehouse will never run out of spare parts, as alerts will notify you when stock replenishment is required.

Practical Use of the CMMS System

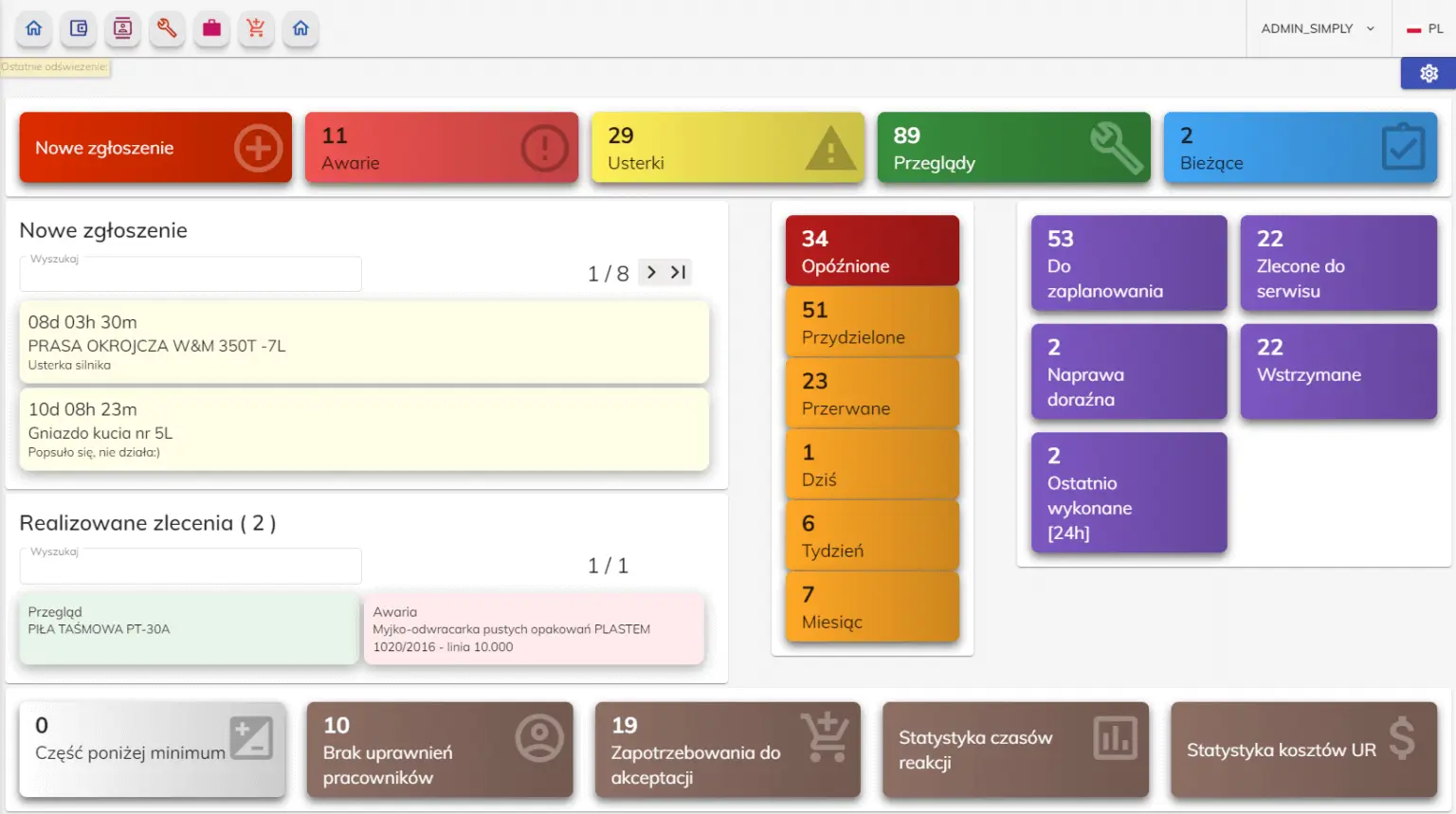

SimplyMobile provides invaluable support to production leaders, machine operators, and maintenance technicians. The CMMS allows easy reporting of breakdowns directly from the production line, significantly reducing the time required to restore operations. Task assignment functionality is essential—progress can be tracked via the appropriate module, and responsible personnel can quickly alert supervisors to any inventory shortages caused by material consumption.

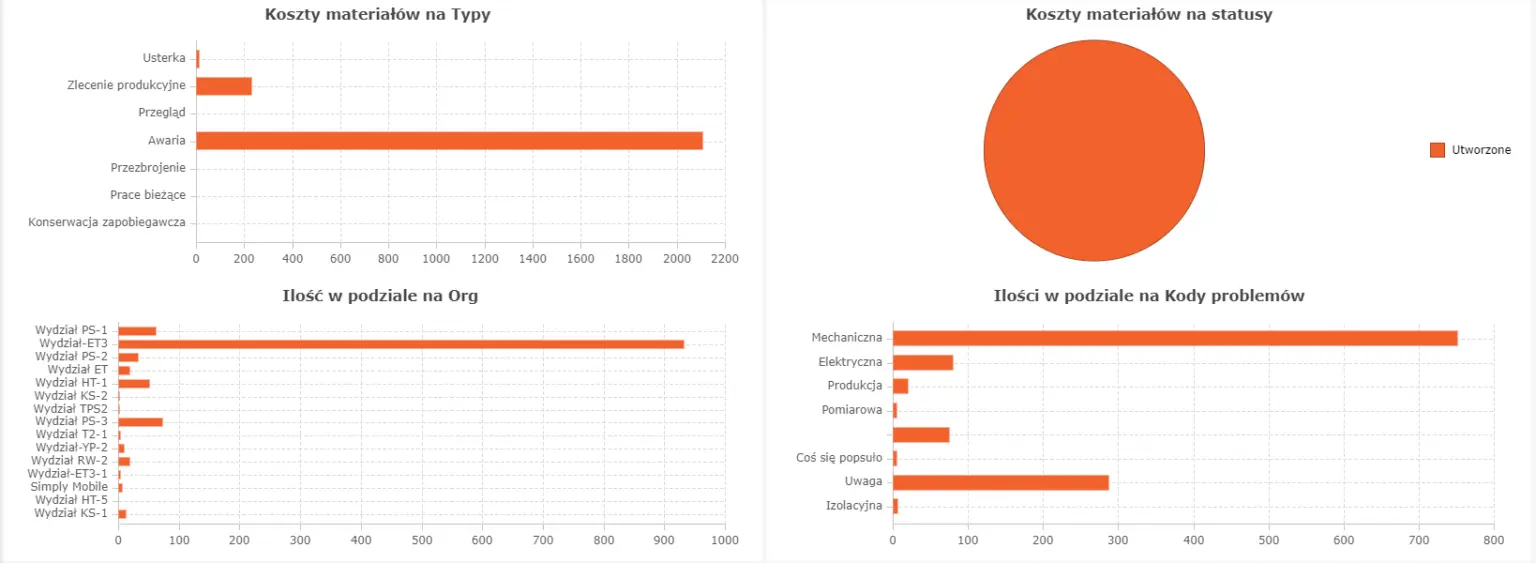

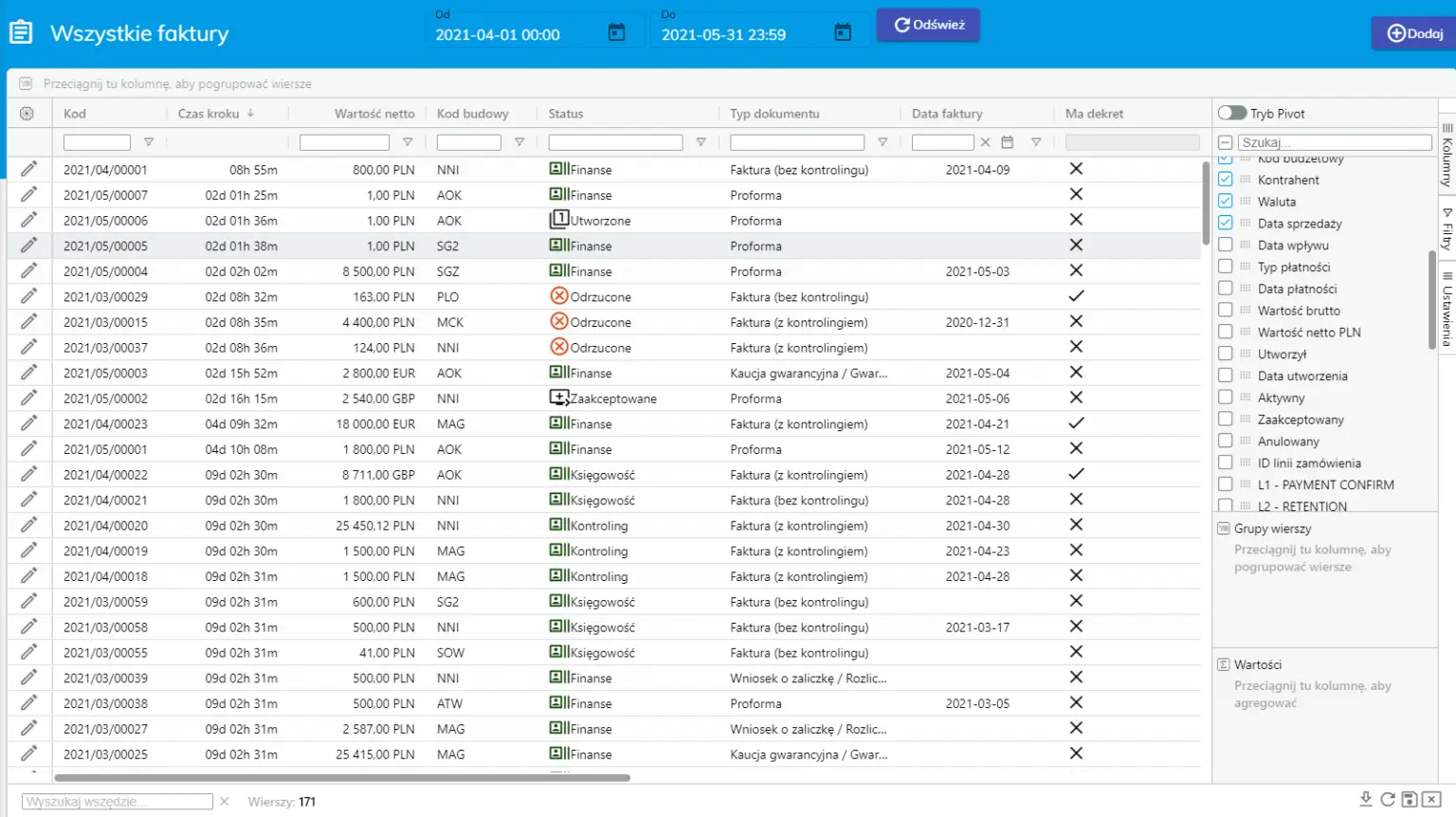

Extensive Reporting Capabilities

The Simply CMMS system enables comprehensive analysis based on available reports as well as custom summaries:

- Work orders and requests

- Labor and parts costs

- Working time

- Purchases

- Invoices

- Plant floor summaries

- Employee schedules

- Others

Rapid CMMS Deployment

We can prepare the system for launch and import initial data very quickly. Thanks to Azure cloud deployment, the application can assist your maintenance department immediately after contacting us.

- Start with a joint teleconference

- Select modules that enable a smooth system start

- Import initial data

- Brief training

- Go-live

- Further system customization

Would You Like to Implement a CMMS or Upgrade Your Existing System?

Keep a few things in mind:

- The system is only as effective as the data entered

- The system must allow for very easy data entry

- Touch panels/mobile devices are essential tools for technicians

- Work/event logging should be online; late entries do not provide equally valuable analytics

If you want to learn more, contact us.

Contact Us

Need an app, consultation, or support for your CMMS/EAM maintenance systems?

FAQ – CMMS System in a Nutshell

- Why is the CMMS system so popular today?

Primarily because it enables optimization and improves the efficiency of the maintenance department. Automation in this area is crucial for resource management, failure response, and preventive actions.

- Why should I implement a CMMS in my plant?

It provides indispensable support to the maintenance department, enabling seamless integration with existing systems and allowing optimization and automation of various production processes.

- Is CMMS a solution for small businesses as well?

Implementing a CMMS enhances operations for any facility with machinery. Regardless of your company's size, this modern support tool will bring significant benefits.

- What are CMMS systems most appreciated for?

Among the main advantages highlighted by users are a single, centralized database; improved communication between the maintenance and production departments; and the ability to adjust production plans based on resource utilization.

- What is the difference between CMMS and EAM systems?

EAM systems focus primarily on asset and fixed-asset management, often overlooking critical aspects needed for maintenance department development. CMMS offers a broader scope of functionality, frequently encompassing features provided by EAM.