PM (Preventive Maintenance)

CMMS / EAM System Knowledge Base

PM (Preventive Maintenance)

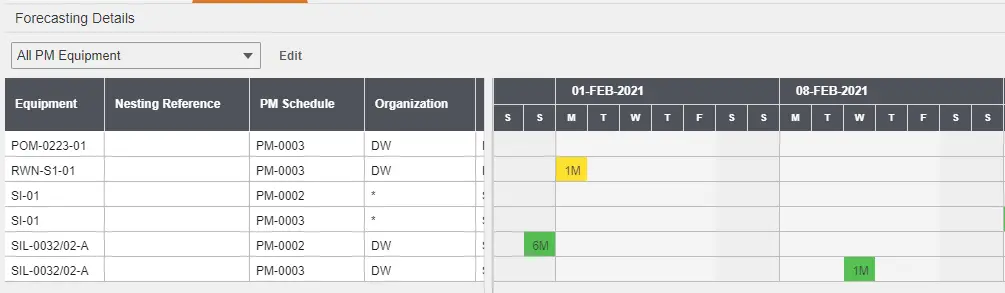

PM, or Preventive Maintenance, is a module of CMMS maintenance management systems where periodic and repeatable tasks are scheduled. Within this module, you define the scope of work to be performed, which should be repeated at specified intervals or when certain parameters are exceeded.

Common triggers for executing PM tasks include:

- A set time interval has elapsed (day/week/month/year, etc.)

- A machine or device has operated for a specified number of motor hours/kilometers/liters, etc.

Reasons for creating preventive maintenance schedules may include:

- Regulatory requirements (e.g., safety inspections)

- Manufacturer’s maintenance manual (OEM recommendations)

- Warranty compliance

- Best practices and experience

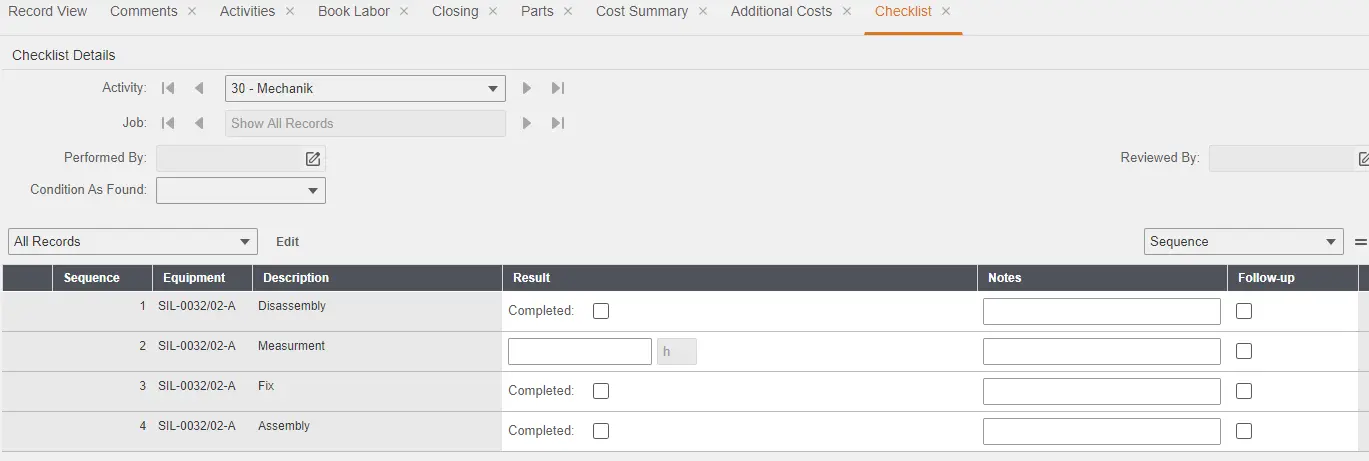

The CMMS maintenance system should allow, along with defining PM tasks, the definition of additional elements such as:

- List of spare parts required for preventive work

- Task list

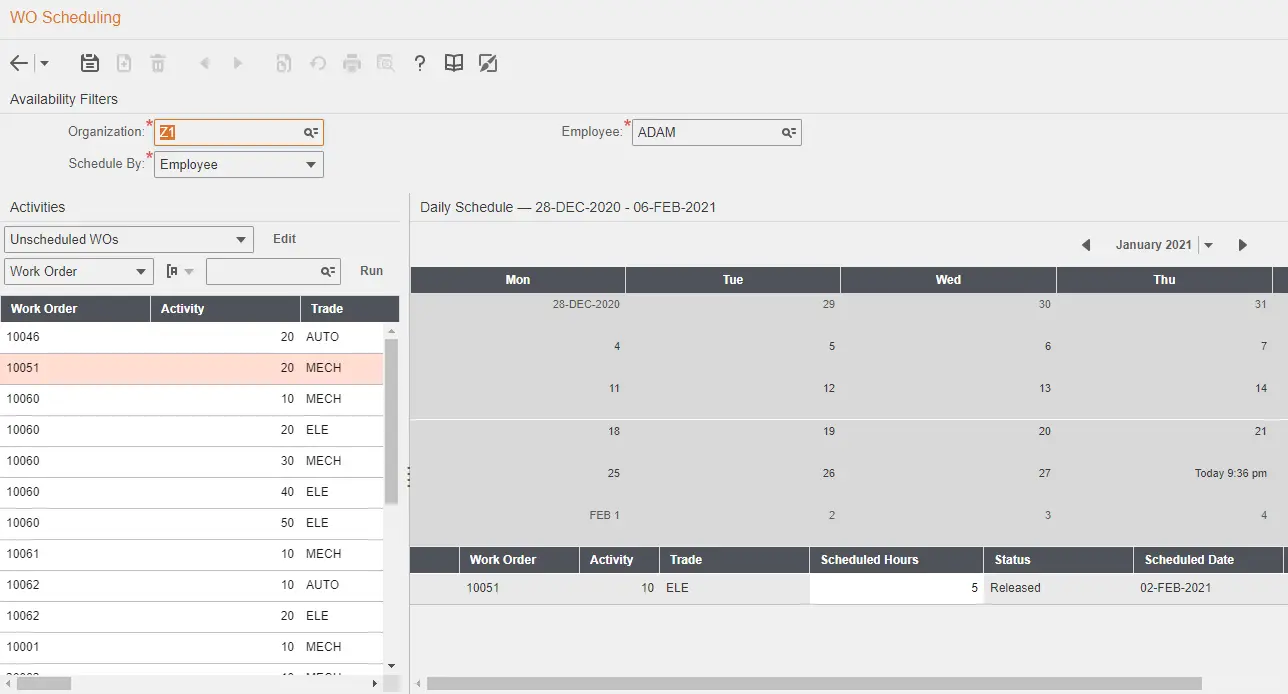

- Specification of labor time and number of personnel needed, including their skill sets

Preventive maintenance aims to reduce failures or unplanned downtime occurring at regular intervals. It is most often related to parts wear.