Production Rounds

Regular, cyclical production rounds enable early detection of anomalies and prompt preventive action, minimizing the risk of equipment failures and unplanned production downtime.

Across numerous production facilities with complex infrastructure, it is vital to carry out thorough, scheduled inspections of critical equipment. In many cases, equipment failures that halted production could have been avoided. The key is to identify irregularities at an early stage and take appropriate preventive or corrective measures.

The standard procedure for these activities is the “shift inspection,” usually performed by production staff as part of the increasingly popular Autonomous Maintenance strategy.

Sometimes technical maintenance teams also conduct these inspections, depending on organizational structure and responsibility assignments. Regardless of which department performs the rounds, the tasks often remain undocumented in any digital system and exist only as paper records.

In theory, a precisely defined inspection route and control checklist guarantee the elimination of failure events, whose occurrence is typically preceded by observable symptoms. Unfortunately, in practice, even a very well-defined inspection scope fails to deliver results if not managed electronically.

It’s worth noting that today’s latest technologies can significantly enhance the effectiveness and efficiency of production rounds.

In many cases, these technologies can complement existing CMMS/EAM systems used for maintenance management.

The core components of such inspection tools include:

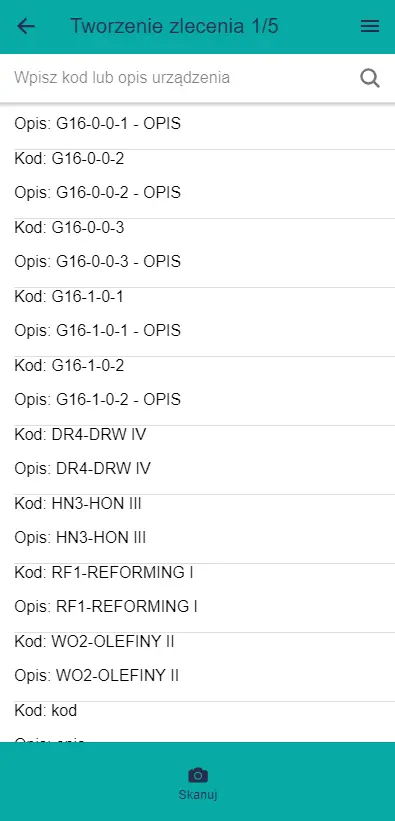

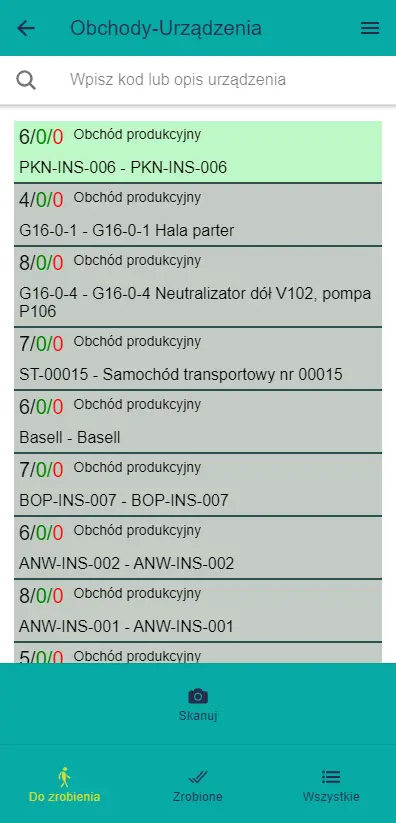

- Recording inspection routes along with scheduled frequencies

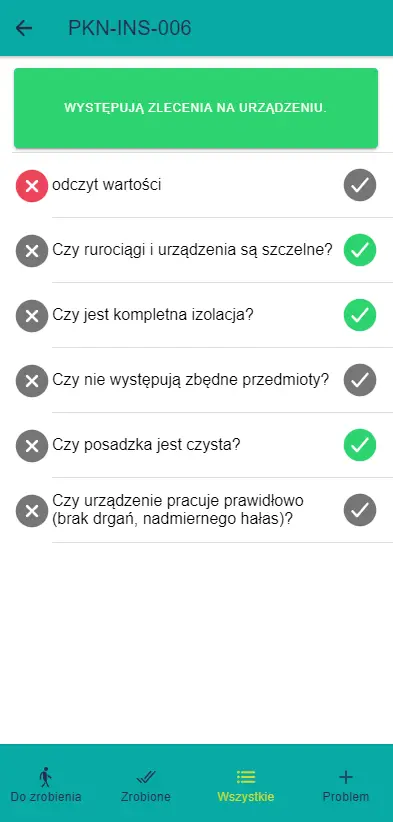

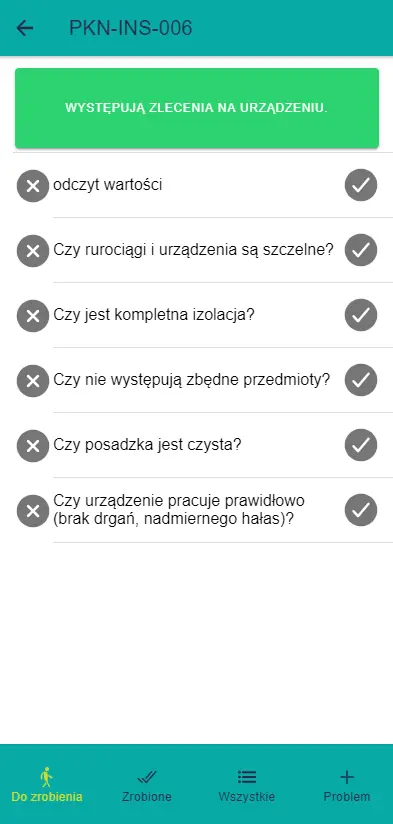

- Defining control checklists for each piece of equipment on the route

- Specifying expected responses from inspectors (e.g., entering measured values or confirming task completion)

- Using a mobile device (tablet or smartphone) to confirm tasks during inspections

- Tagging inspection waypoints with RFID/NFC to enforce presence and streamline data capture

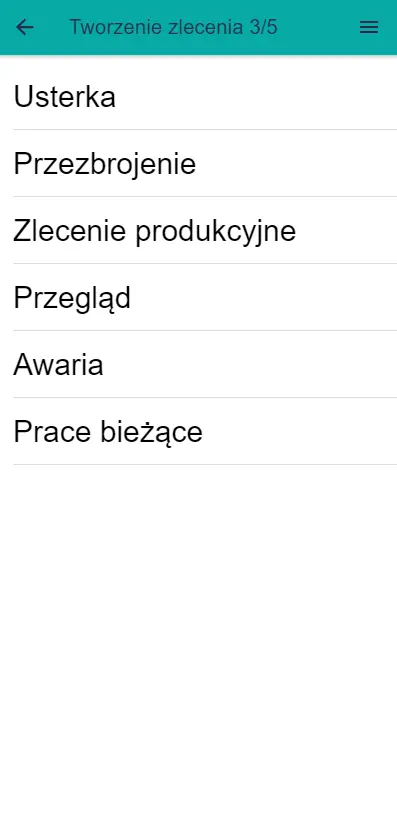

- A quick-capture mechanism for logging identified issues with categorization and photo documentation

- An intuitive dashboard for analyzing and overseeing completed production rounds

- Automated alerts for any detected irregularities